제품 설명

Good quality Metal Sheet and Tube Fiber Laser Cutting Machine Used in Agricultural Equipment

제품 특징

Imported high precision ball screw/ rack and pinion transmission, high precision linear guide rail.

Imported servo motor driving system , imported helical gearbox.

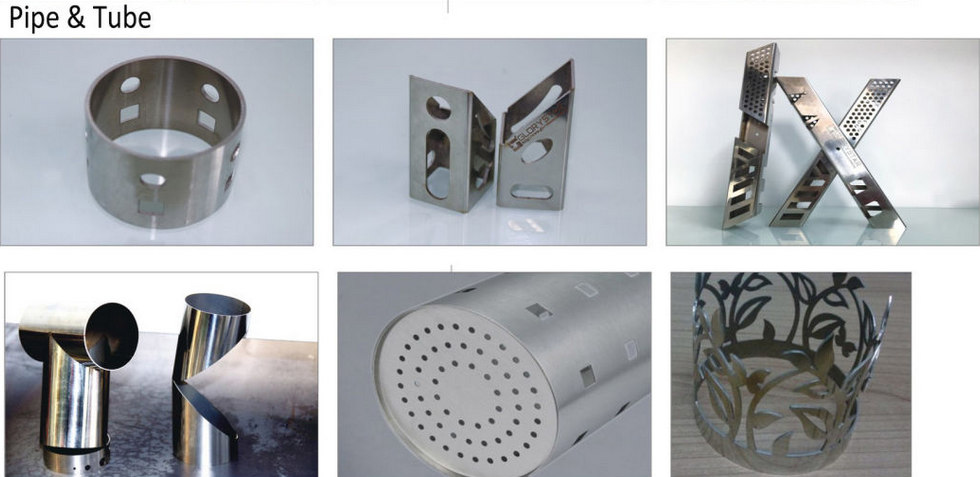

Separate cutting tube device.

Fast cutting speed, high efficiency,safe, stable performance.

Good quality Metal Sheet and Tube Fiber Laser Cutting Machine Used in Agricultural Equipment

기술 데이터

| 레이저 파워 | 500W-8000W(옵션) |

| 업무 공간 | 3000 * 1500mm |

| 총 소비 전력 | 10Kw<60Kw |

| 전송 모드 | Gear and Rack Double drive |

| 전압 및 주파수 | 380V 50Hz(60Hz) |

| 치수 | 4800*3260*1750mm |

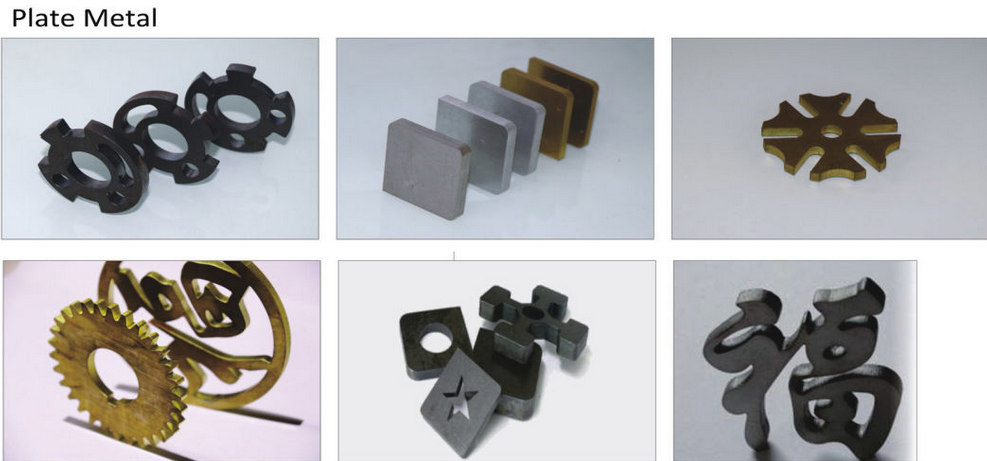

적용 가능한 재료

Mainly applied to all kinds of sheet metal materials with non-contact fast cutting,hollowing and punching. Such as mild steel, stainless steel, alloy steel, manganese steel,galvanized, aluminum, copper and metal pipe processing, etc.

해당 산업

Widely used in all kinds of metal products industries such as sheet metal processing, kitchen ware and bathroom ,advertising & signs, lighting & hardware,electrical cabinets, auto parts,machinery and equipment, household appliance,elevator and precision parts processing ,etc.

기본 정보

레이저 기술 : 레이저 제어 결함 절단

Automation: Automatic

Type for Cutting Machine: Laser Cutting Machine

Type: Metal Laser Cutting Machine

레이저 타입 : 섬유 레이저

Cutting Acurancy: 0.01mm

조건 : 새로운

Certification: GS, Ce, ISO9001, SGS

Standard: GB

Customized: Non-Customized

Material: Metal

상표 : ACCURL

Transport Package: Seaworthy Plywood Case

Specification: CE SGS FDA ISO

원산지 : Anhui, China

HS 코드 : 8456100090

Sample Show

| 1000W fiber laser cutting machine cutting parameters | |||||||

| 자료 | 절단 두께 (mm) | Cutting speed(m/min) | Cutting gas | Cutting pressure | 대통 주둥이 | Collimator / Focus | Remarks |

| 탄소강 | 0.5 | 30-40 | 공기 | 6 | 1.5 single layer | 75/125 | Please adjust accord to actual focal position by cutting head, all parameters for reference |

| 0.8 | 20-25 | 공기 | 8 | 1.5 single layer | 75/125 | ||

| 1 | 18-22 | 공기 | 10 | 2.0 single layer | 75/125 | ||

| 2 | 5-6.5 | 산소 | 3.5 | 1.2 double layer | 75/125 | ||

| 3 | 3-3.5 | 산소 | 0.5-1 | 1.2 double layer | 75/125 | ||

| 4 | 2-2.3 | 산소 | 0.5 | 1.2 double layer | 75/125 | ||

| 5 | 1.5-1.8 | 산소 | 0.5 | 1.2 double layer | 75/125 | ||

| 6 | 1.2-1.4 | 산소 | 0.5 | 1.5 double layer | 75/125 | ||

| 8 | 0.9-1.2 | 산소 | 0.5 | 2.0 double layer | 75/125 | ||

| 10 | 0.7-0.8 | 산소 | 0.5 | 2.5 double layer | 75/125 | ||

| 12 | 0.5-0.65 | 산소 | 0.5 | 2.5 double layer | 75/125 | ||

| 스테인레스 | 0.5 | 30-40 | 질소 | 7 | 1.5 single layer | 75/125 | |

| 0.8 | 22-25 | 질소 | 10 | 1.5 single layer | 75/125 | ||

| 1 | 20-23 | 질소 | 12 | 1.5 single layer | 75/125 | ||

| 2 | 6-7 | 질소 | 15 | 2.0 single layer | 75/125 | ||

| 3 | 2.5-2.8 | 질소 | 18 | 2.0 single layer | 75/125 | ||

| 4 | 0.8-1.2 | 질소 | 18 | 2.0 single layer | 75/125 | ||

| 5 | 0.6-0.8 | 질소 | 18 | 2.0 single layer | 75/125 | ||

| 알류미늄 | 0.5 | 20-25 | Air / Nitrogen | 8 | 1.5 single layer | 75/125 | |

| 0.8 | 15-18 | Air / Nitrogen | 9 | 1.5 single layer | 75/125 | ||

| 1 | 10-12 | Air / Nitrogen | 12 | 1.5 single layer | 75/125 | ||

| 2 | 3-3.5 | Air / Nitrogen | 18 | 2.0 single layer | 75/125 | ||

| 3 | 1-1.5 | Air / Nitrogen | 18 | 2.0 single layer | 75/125 | ||

| 놋쇠 | 0.5 | 22-30 | 질소 | 12 | 1.5 single layer | 75/125 | |

| 0.8 | 13-17 | 질소 | 12 | 1.5 single layer | 75/125 | ||

| 1 | 10-12 | 질소 | 15 | 1.5 single layer | 75/125 | ||

| 2 | 2-3 | 질소 | 18 | 2.0 single layer | 75/125 | ||

| 3 | 1-1.3 | 질소 | 18 | 2.0 single layer | 75/125 | ||

| 구리 | 0.5 | 15-18 | 산소 | 12 | 1.5 single layer | 75/125 | |

| 0.8 | 8-12 | 산소 | 12 | 1.5 single layer | 75/125 | ||

| 1 | 5-7 | 산소 | 12 | 1.5 single layer | 75/125 | ||

| 2 | 0.8-1.2 | 산소 | 15 | 2.0 single layer | 75/125 | ||